shopping cart is empty

Brew

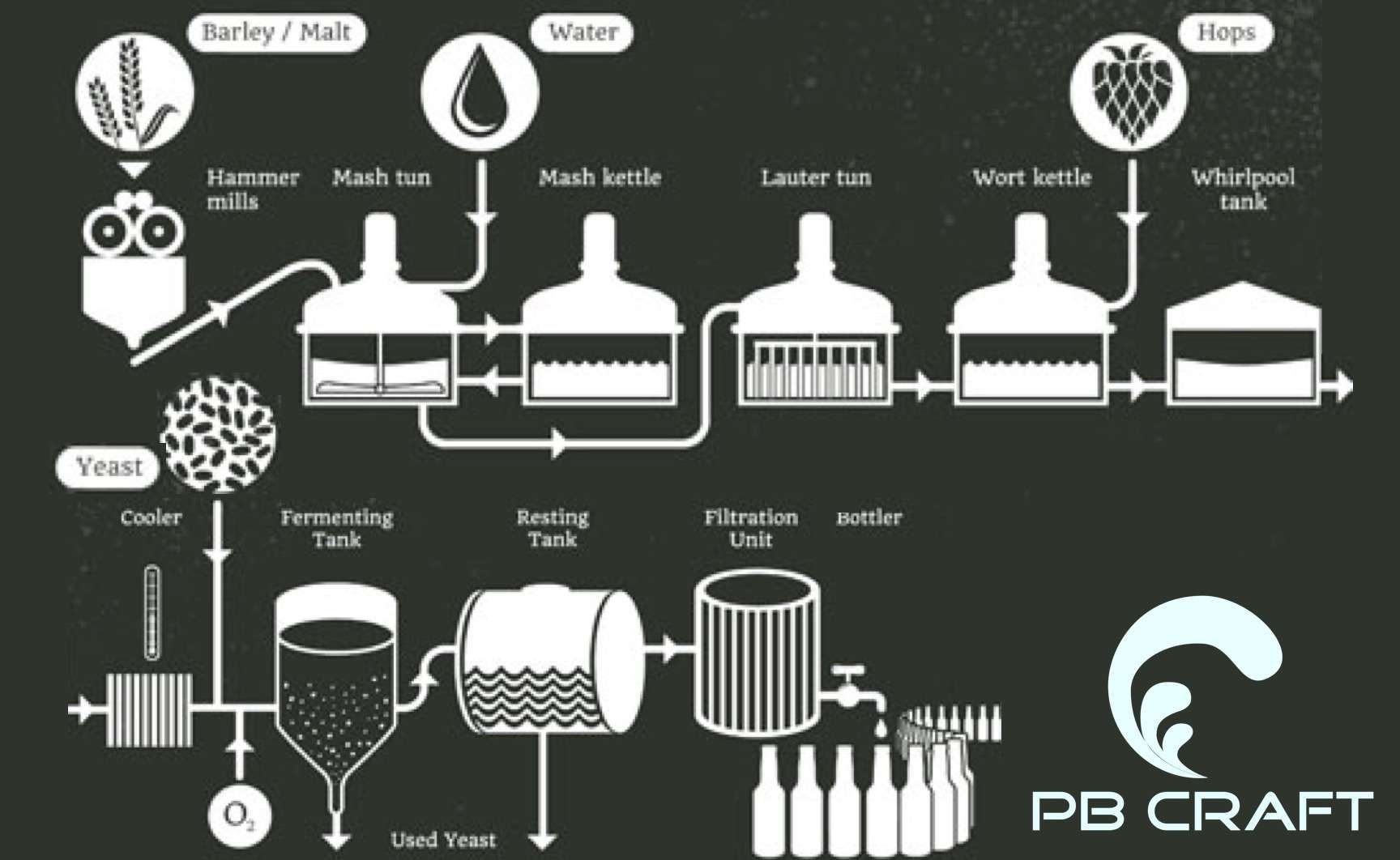

Beer brewing is simply converting cereal starch into a sugary liquid called "wort", which is then mixed with yeast for fermentation, after the fermentation the wort will turn into liquid containing alcohol and bubbles known as beer.

The first step in brewing is mashing. At this stage, hot water is mixed with the crushed malt to make mixed liquor, "mash". After mash has been rested in the pot for 1 to 2 hours, the starch from mash will be is converted into sugar, and then the sweet wort is the only part that we will keep, leaving behind the grain.

After mashing, the next step is sparge. Sparge serves the purpose of extracting as much fermentable wort as possible from the sweet wort. The process of filtering wort from malt is called wort separation. The traditional wort separation method uses malt skin as the natural filter layer, while modern breweries use mechanical filter presses to increase production efficiency. You can also use fly sparge to collect more wort fly sparge means collecting multiple times from the same batch. This technique can be used according to the production volumn. Each batch of wort produces a different taste, therefore, fly sparge is also called "batch sparge brewing".

Following by sparge, boiling is needed. The water in the wort will gradually evaporate in the boiling process that lasts for about 1 hour, but the sugar and other ingredients will remain. The wort boiling process also destroys the enzyme in the mash; enzyme is something that we do not want in our delicious beer. Hops are added to the pot at this stage as well giving the beer a bitter taste and aroma. Hops can be added separately throughout different stages if wanted. The longer the hops is boiled, the more bitterness and less aroma there is.

When wort is cooled off, it can be loaded into the fermentation tank and added with yeast. The fermentation process takes about 7 days to 1 month. The fermentation time depends on the type of yeast and the type of beer one wants to brew. The suspended particles in the wort will gradually precipitate during the fermentation process, and the yeast will settle to the bottom of the solution at the end of the fermentation, forming a bottom residue.

The fermentation is usually carried out in two stages. At this time, the beer will be moved to another container to add sugar for secondary fermentation (similar to champagne). The purpose of the second fermentation is to extend the shelf life of the beer and also improve the clarity and gas content of the beer. The beer after fermentation will be packed in beer barrels, keg, aluminum cans or glass bottles.

In our store, we have everything you need to brew a lovely glass of beer!

Home brewing flowchart

OG/FG/Alc conversion table

Fun fact:

Generally, in order to make the beer remains its stable state, pasteurization or instant high temperature sterilization is used before and after bottling, and to stop the yeast reaction. Compared to draft beer, the sterilized beer has higher stability and greater shelf life. Although draft beer is relatively intolerant to storage, it retains a fresher and more refreshing taste.

The first step in brewing is mashing. At this stage, hot water is mixed with the crushed malt to make mixed liquor, "mash". After mash has been rested in the pot for 1 to 2 hours, the starch from mash will be is converted into sugar, and then the sweet wort is the only part that we will keep, leaving behind the grain.

After mashing, the next step is sparge. Sparge serves the purpose of extracting as much fermentable wort as possible from the sweet wort. The process of filtering wort from malt is called wort separation. The traditional wort separation method uses malt skin as the natural filter layer, while modern breweries use mechanical filter presses to increase production efficiency. You can also use fly sparge to collect more wort fly sparge means collecting multiple times from the same batch. This technique can be used according to the production volumn. Each batch of wort produces a different taste, therefore, fly sparge is also called "batch sparge brewing".

Following by sparge, boiling is needed. The water in the wort will gradually evaporate in the boiling process that lasts for about 1 hour, but the sugar and other ingredients will remain. The wort boiling process also destroys the enzyme in the mash; enzyme is something that we do not want in our delicious beer. Hops are added to the pot at this stage as well giving the beer a bitter taste and aroma. Hops can be added separately throughout different stages if wanted. The longer the hops is boiled, the more bitterness and less aroma there is.

When wort is cooled off, it can be loaded into the fermentation tank and added with yeast. The fermentation process takes about 7 days to 1 month. The fermentation time depends on the type of yeast and the type of beer one wants to brew. The suspended particles in the wort will gradually precipitate during the fermentation process, and the yeast will settle to the bottom of the solution at the end of the fermentation, forming a bottom residue.

The fermentation is usually carried out in two stages. At this time, the beer will be moved to another container to add sugar for secondary fermentation (similar to champagne). The purpose of the second fermentation is to extend the shelf life of the beer and also improve the clarity and gas content of the beer. The beer after fermentation will be packed in beer barrels, keg, aluminum cans or glass bottles.

In our store, we have everything you need to brew a lovely glass of beer!

Home brewing flowchart

OG/FG/Alc conversion table

Fun fact:

Generally, in order to make the beer remains its stable state, pasteurization or instant high temperature sterilization is used before and after bottling, and to stop the yeast reaction. Compared to draft beer, the sterilized beer has higher stability and greater shelf life. Although draft beer is relatively intolerant to storage, it retains a fresher and more refreshing taste.